TECHNICAL CHARACTERISTICS

Autwomatic: Production of Type II Water (Analytical Grade) according to ASTM D1193 and ISO 3696 standards

Equipment for production of Type II Water for laboratory use, with production capacity from 3 to 10 l/h.

|

Versions |

Liter /hour |

Purification Module |

UV Lamp |

Final Filter 0.22 micron |

|

AUTWOMATIC 3 |

3 |

X |

- |

- |

|

AUTWOMATIC 5 |

5 |

X |

- |

- |

|

AUTWOMATIC 10 |

10 |

X |

- |

- |

Based on a sequential purification (sediments filtration, dechlorination, reverse osmosis, deionization).

It can also supply, at the same time, osmotic water to thermo-disinfectors and autoclaves.

Freshly produced Water Type II, with no accumulation in a final tank

Water Type II dispensed by the equipment is always freshly produced. Differently from other equipments, there is no storage of the final water, in order to avoid its deterioration.Oursystems storetheosmotizedwater intopressure tank.

Storage Tanks

The Autwomatic is designed to work with pressure vessels, ensuring a better quality of Final Water both ions as a microbiological level.

Pressure tanks of 30 and 50 liters.

|

Dimensions (mm) |

||||

|

Ref |

Denomination |

Height |

Diameter |

|

|

7022 |

Pressure Tank 30 L |

600 |

400 |

|

|

7023 |

Pressure Tank 50L |

800 |

400 |

|

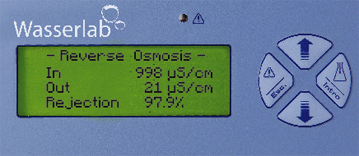

Monitoring

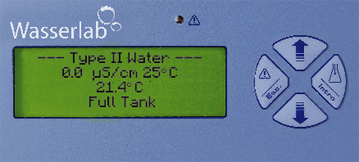

Continuous monitoring of the purification process parameters:

- Real number of working hours of the equipment.

- Feed water conductivity (± 1 mS/cm).

- Osmotic water conductivity (± 1 mS/cm)

- % performance of the reverse osmosis module (± 0,1%).

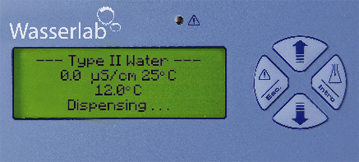

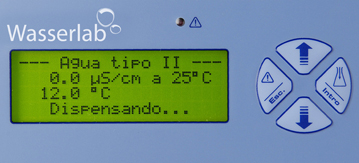

- Conductivity of the produced Type II water (± 0,1 mS/cm).

- Water temperature. All conductivity measurements are compensated at 25ºC.

- Status of the equipment (producing/full tank/dispensing).

Automatic operation

The equipment starts and stops automatically, thus guarantying the production of Type II Water. Automatic stop in case of water supply cut.

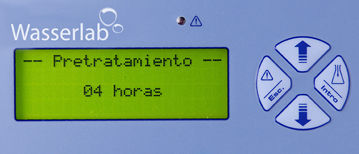

Parameters customizing

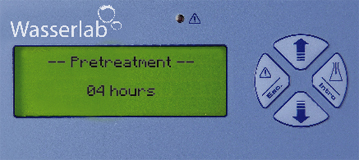

The user can fix different parameter values, according to the control requirements:

- Pre-treatment time.

- Minimum performance of the reverse osmosis module.

- Maximum conductivity of the produced Type II water.

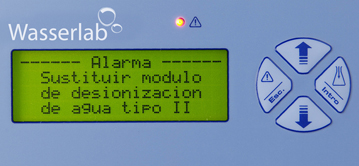

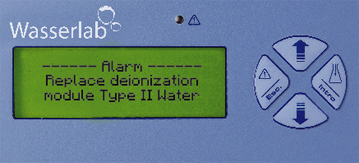

Warnings

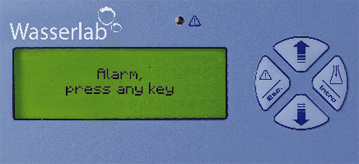

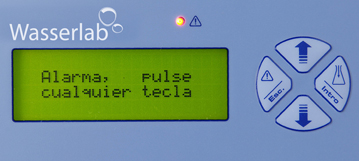

The equipment warns, by a visual and audio message, of the need to replace the consumables, according to the fixed values:

- Pre-treatment change

- Interchange resin change

- Change of the reverse osmosis module

- Warning of malfunction of conductivity and temperature probes

Conductivity meter calibration and system verification

Autwomatic software allows the adjustment and calibration of the conductivity meter by a traceable certified standard, according to the national standards of the German Deutscher Kalibrierdienst (DKD).

Wasserlab’s Technical Assistance Service offers, at user request:

1. Periodic equipment calibration service.

2. Complete system verification, with the extension of the relevant certificate.