“Ultrapure water of the highest quality for the most critical applications in your laboratory“

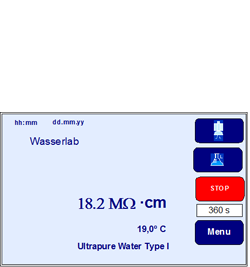

“Touch screen control“

The range of equipment Ultramatic Plus supply Ultrapure water of the highest quality, exceeding ASTM specifications for Type I Water , starting from purified water (Type II, distilled or RO), incorporating the highest technologies in the production and control Ultrapure Water quality obtained.

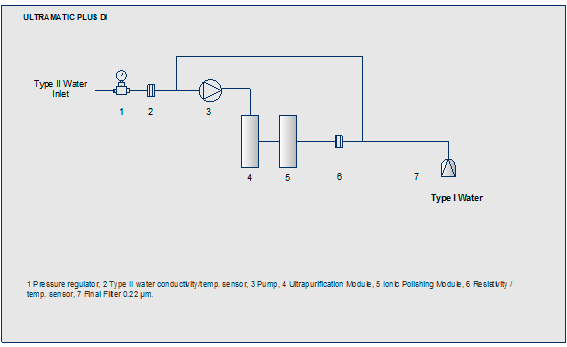

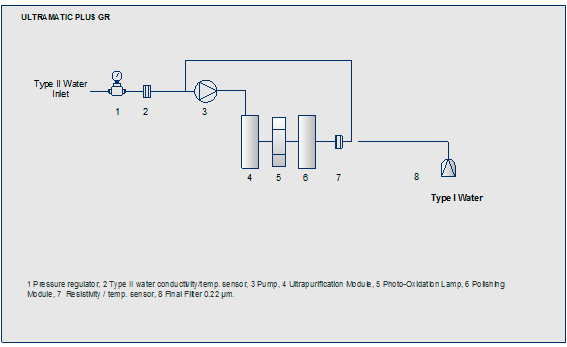

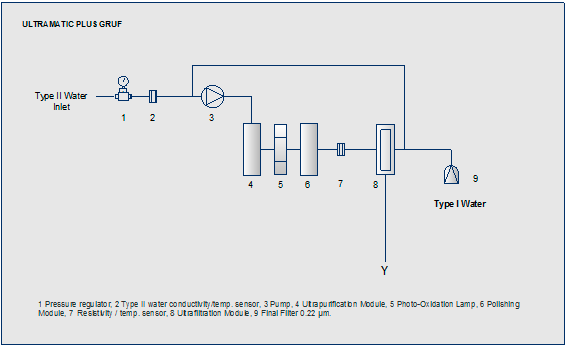

Configurations Ultramatic Plus model

| Versions | Code | Ultrapure Water Type I | ||||||

| Production rate | Ultrapurification module | Ioinic polishing module | Foto-Oxidation Lamp | Polishing module | Ultrafiltration module | Final Filter 0,22 μm | ||

| Ultramatic Plus DI | QUDI0011 | 2 l/min | X | X | - | - | - | X |

| Ultramatic Plus GR | QUGR0011 | 2 l/min | X | - | X | X | - | X |

| Ultramatic Plus GRUF | QUGF0011 | 2 l/min | X | - | X | X | X | X |

Qualities of the Water

| Model | Ultramatic Plus DI | Ultramatic Plus GR | Ultramatic Plus GRUF |

| Dispensation | 2 l/ min | 2 l/ min | 2 l/ min |

| Resistivity | 18,2 MΩ.cm | 18,2 MΩ.cm | 18,2 MΩ.cm |

| TOC | < 10 ppb | < 3 ppb | < 3 ppb |

| Bacteria | < 0.01 ufc/ml | < 0.01 ufc/ml | < 0.01 ufc/ml |

| Endotoxins | - | - | < 0,001 EU/ml |

| Particles | 0,22 µm | 0,22 µm | Ultrafiltración |

| Rnasas y Dnasas | - | - | Removal |

|

Applications |

Analysis of inorganic traces, AA, IC ,ICP-MS, Photometry |

Analytical methods such as analisys of organic and inorganic traces, HPLC, ICP-MS, IC and TOC analysis. |

Molecular Biology, Cell Culture, PCR, DNA sequencing, Monoclonal antibody production. |

Stages Ultra Water Purification

Ultrapurification Module (Ultramatic Plus GR y GR UF)

Purified feed water passes through a Ultrapurification Module reducing trace levels of ionic contaminants, until a resistivity of 18.2 MΩ.cm.

Ionic Polishing Module (Ultramatic Plus DI)

Final deionization by ion exchange resin beds to remove ionic contaminants at trace levels, obtaining Ultrapure Water (Type I) with a resistivity of 18.2 MΩ.cm

Foto – Oxidation Module (Ultramatic Plus GR y GRUF)

It Reduces organic pollution at trace levels emitting Ultraviolet radiation at 254 nm with germicidal action and radiation at 185 nm with ability to oxidize organic compounds dissolved in the water to be retained by the Ionic Polishing Module, eliminating traces of ions in the Ultrapure Water to obtain a resistivity of 18.2 MΩ.cm.

Polishing Module (Ultramatic Plus GR y GRUF)

Reduction of organic matter (TOC) removing traces of ions in Ultrapure Water to obtain a resistivity of 18.2 MΩ.cm

Ultrafiltration Module (Ultramatic Plus GRUF)

For critical applications in Molecular Biology (PCR, DNA sequencing, Cell Culture, Electrophoresis) a hydrophilic hollow fiber membrane encapsulated, large filtering surface (0.56 m²), eliminates bacteria, pyrogens and nucleases present in the water

Final Filter 0,22 µm:

Final amicrobic encapsulated Filter 0.22 micron, high-flow membrane and removable free for particle retention and bacterial count ≤0.01 cfu /ml.

Dispensation

The Ultramatic Plus allows three types of dispensing:

- Continuous

- Volumen wise

- Time control

Monitoring

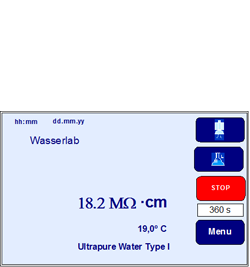

Through a touch screen of 4.3 ", the Ultramatic Plus monitors all process parameters ultra water purification equipment.

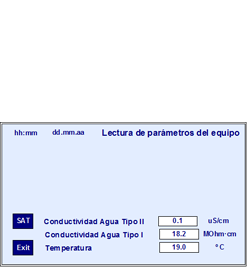

Water Quality

- Measurement of inlet water conductivity (µS/cm)

- Measurement of the Resistivity of Type I Water (MΩ·cm)

- Water temperature (° C)

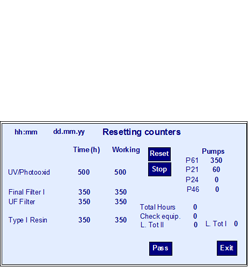

Parameter Control

- Working hours of the different elements.

- Hours of operation of the equipment.

- Total Liters produced

Security

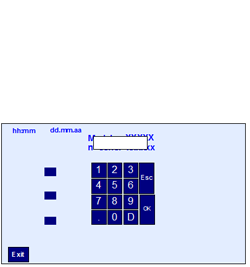

The system have passwords to allow access to different parts of the menu, as well as access to certain functions such as:

- Access to the configuration menus and reset counters.

- Luggage maximum conductivity value admitted.

- Define the type of dispensation.

Automatisms

Type I Water recirculation programmable:

• Automatic scheduled recirculation System of the water in your circuit, ensuring the highest quality of water dispensed.

• Inability to dispense Type I Water with less than a preset value of resistivity.

The system warns the change of consumables as well as anomalies like inlet water cut, or malfunction of the measuring probes.

Maintenance, sanitization and calibration

Very simple system to use and maintain.

Very fast change of consumables, cartridges equipped with fast connection and anti-drip system.

Possibility of sanitize the hydraulic circuit.

Equipment calibrated using certified standard traceable to national standards DKD

CE marking.