TECNICAL CHARACTERISTICS

Type II Water (Analytical Grade): Purified Water supply for machines and industrial processes

Autwomatic High production models produce from 20 to 120 l/h Type II Purified Water from tap water.

|

Versions |

Liter/hour |

Purification Module |

UV Lamp |

Final filter 0.22 micron |

By Pass Security |

|

AUTWOMATIC PROCCESS 20 |

20 |

X |

- |

- |

X |

|

AUTWOMATIC PROCCESS 20 UV |

20 |

X |

X |

X |

X |

|

AUTWOMATIC PROCCESS 40 |

40 |

X |

- |

- |

X |

|

AUTWOMATIC PROCCESS 40 UV |

40 |

X |

X |

X |

X |

|

AUTWOMATIC PROCCESS 60 |

60 |

X |

- |

- |

X |

|

AUTWOMATIC PROCCESS 60 UV |

60 |

X |

X |

X |

X |

|

AUTWOMATIC PROCCESS 90 |

90 |

X |

- |

- |

X |

|

AUTWOMATIC PROCCESS 90 UV |

90 |

X |

X |

X |

X |

|

AUTWOMATIC PROCCESS 120 |

120 |

X |

- |

- |

X |

|

AUTWOMATIC PROCCESS 120UV |

120 |

X |

X |

X |

X |

Based on a sequential purification steps (sediment filtration, dechlorination, reverse osmosis, deionization, Ultraviolet treatment and final filtration of 0.22 micron.

Ideal to supply water to industrial processes and machines requiring purified water with the lower cost per liter.

Reduces drastically the number of stops to make changes of resin. Easy, simple and fast maintenance.

Monitoring

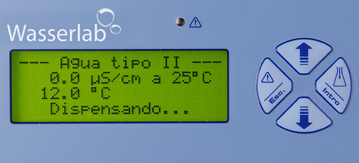

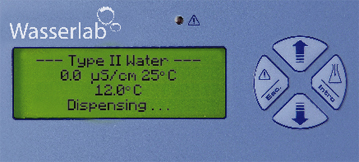

Continuous monitoring of the purification process parameters:

- Real number of working hours of the equipment.

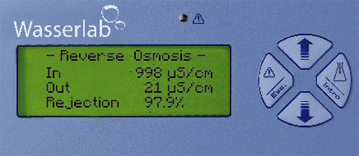

- Feed water conductivity (± 1 mS/cm).

- Osmotic water conductivity (± 1 mS/cm)

- % performance of the reverse osmosis module (± 0,1%).

- Conductivity of the produced Type II water (± 0,1 mS/cm).

- Water temperature. All conductivity measurements are compensated at 25 ºC.

- Status of the equipment (producing/full tank/dispensing).

Automatic operation

The equipment starts and stops automatically, thus guarantying the production of Type II Water. Automatic stop in case of water supply cut.

Parameters customizing

The user can fix different parameter values, according to the control requirements:

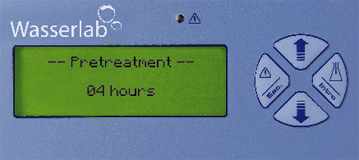

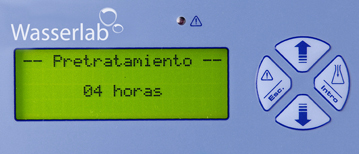

- Pre-treatment time

- Minimum performance of the reverse osmosis module.

- Maximum conductivity of the produced Type II water.

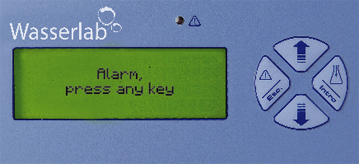

Warnings

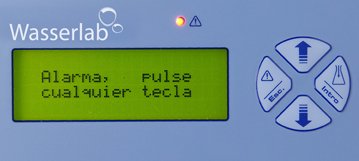

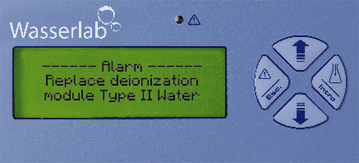

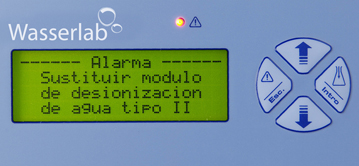

The equipment warns, by a visual and audio message, of the need to replace the consumables, according to the fixed values.

- Pre-treatment change

- Interchange resin change

- Change of the reverse osmosis module

- Warning of malfunction of conductivity and temperature probes

The equipment warns by a visual ans audio message of the need to replace consumables, according to the fixed values.

In accordance with the requirements of processes, it can be included in the equipment:

Ultraviolet lamp (UV Version)

The disinfection equipment emits ultraviolet radiation in two wave lengths, leading to a reduction of the bacterial content of 5 logaritmic cycles. This provides the user with water with minimum bacterial contamination if needed and produces the oxidation of organic material traces in the water.

Security system via By-pass

System that allows a production of Type II Water directly from tap water in case of equipment is stopped.

Security system by double sensor monitorization

It is possible to use two conductivity sensors of Type II Water. This allows to detect that first deionization module is exhausted. On this way it allows to plan maintenance operations on time and assuring the continuous work of processes.