TECNICAL CHARACTERISTICS

Ultramatic: the system for High Production of Type I Ultrapure water (Reagent Grade)

The Ultramatic produces Ultrapure Water Type I (Reactive Grade) according to ASTM D1193, and ISO 3696 standards, with production of 4 and 6 l/min covering the different needs of purity that each user can have in accordance with the method of analysis.

|

Versions |

Ultrapurification Module |

Fotooxidation Lamp |

Ultrafiltration Cartridge |

Final Filter 0.22 micron |

|

ULTRAMATIC MAXI GR |

X |

X |

- |

X |

|

ULTRAMATIC MAXI GRUF |

X |

X |

X |

X |

Features

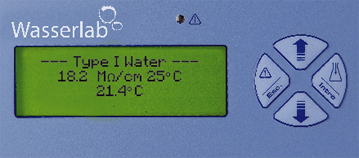

The Ultramatic produces Ultrapure Water –Type I – Reactive Grade from pre-purified water: Resistitvity 18.2 MΏ·cm at 25 ºC, TOC < 10 ppb y bacterial count <=1 cfu/ml. Prepurified feed water could be:

Ultrapure water is achieved through sequential steps:

Photooxidation

Ultramatic model uses a dual wavelength which emits Light at:

Ultrafiltration: Removing pyrogens and nucleases

Ultrafiltration module is used in critical applications of Molecular Biology (PCR, DNA sequentiation, celular cultures, electrophoresis, …) when pyrogens and nucleases have to be removed.

Resistivity measurement

Ultramatic used a inline resistivity sensor to measure the electrical resistivity of produced water (± 0,1MΏ·cm) with temperatura compensation (± 0,1 ºC).

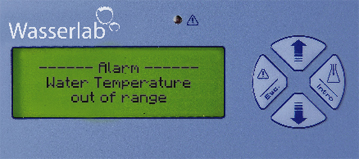

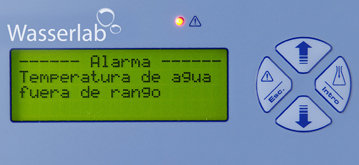

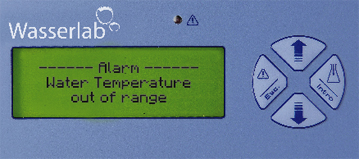

As a security mechanism for the user, the software includes a prefixed set point (10 MΏ.cm) below which water is not dispensed.

Automatic recirculation

Ultramatic recirculates automatically the water in the circuit to ensure the highest quality of water dispensed.

Models with Ultrafiltration module perform a recirculation and drainage of UF module periodically.